Screen O Tex is proud to unveil its new range of VEGA Screens®, which set a whole new benchmark for fine print technology. The demand for sophisticated and fine prints among textile printers are rising constantly, this product is specifically designed to cater to fine and highly detailed printing requirements. The unique combination of high mesh count along with higher thickness and higher open area minimizes most problems being faced by end users.

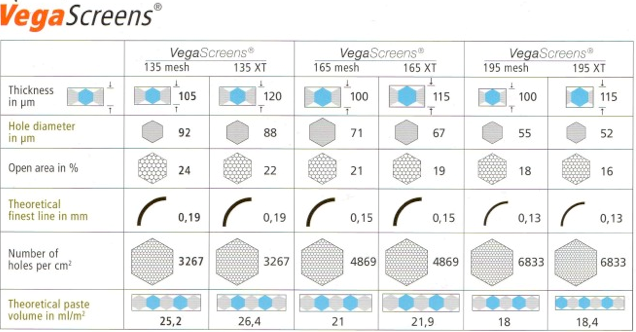

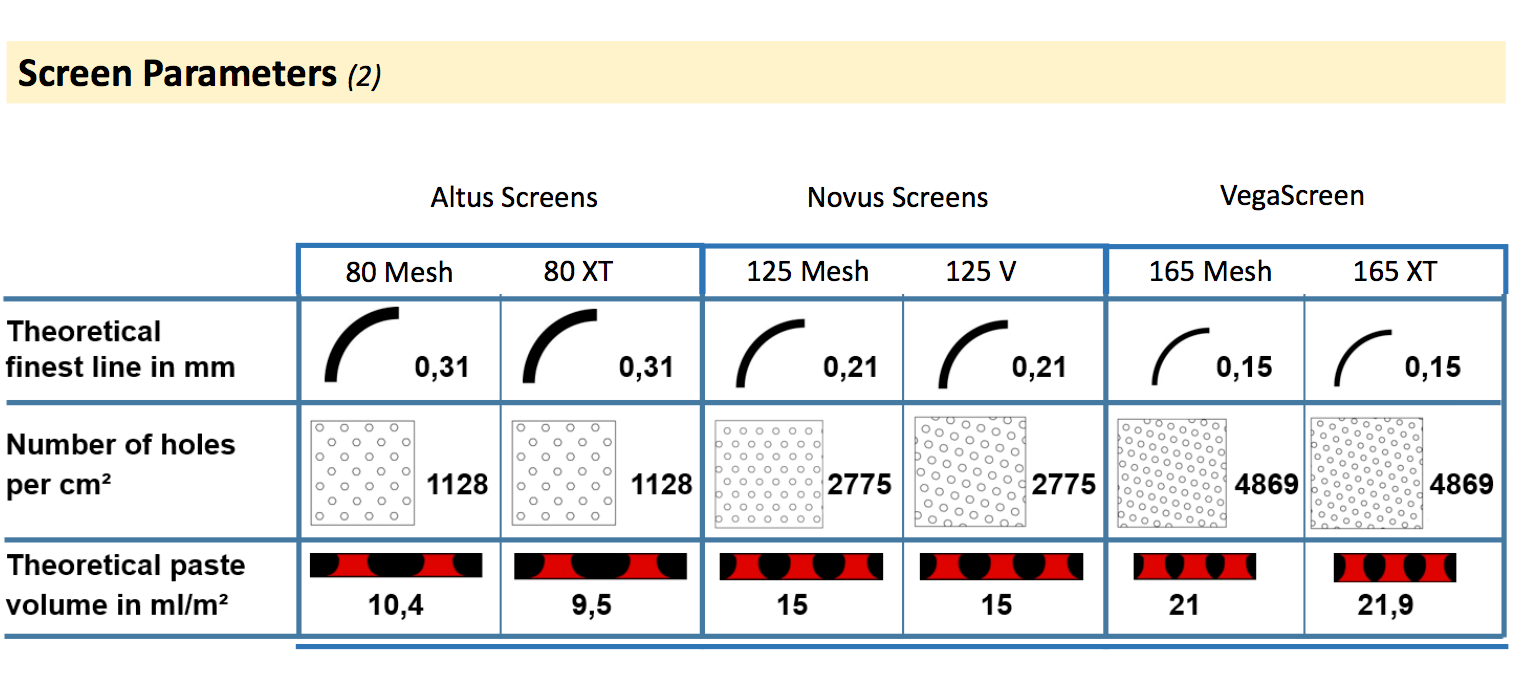

The range of VEGA Screens® consists of 3 different mesh counts. All the mesh counts have two variants, a standard product i.e. 135, 165 and 195. These consist of the standard parameters that are normally used. We also offer 135XT, 165XT and 195XT. The XT range, has different parameters, for your special printing needs it offers a number of variations so that you can get the a product best suited for your needs.

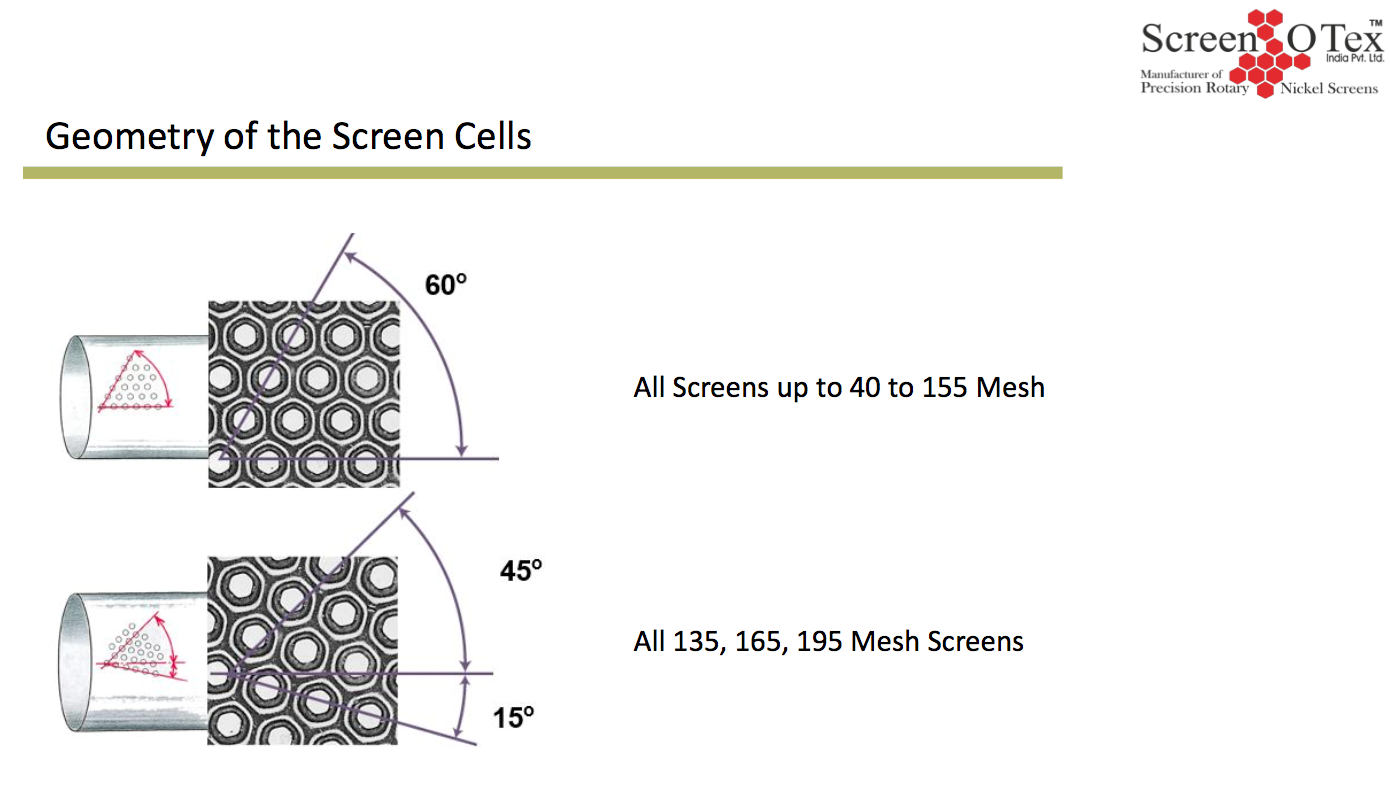

The characteristic that make Vega screens different:

Available Mesh Count: 135 / 135 XT, 165 / 165 XT and 195 / 195 XT

Available Mesh Count: 135 / 135 XT, 165 / 165 XT and 195 / 195 XT

Advantages:

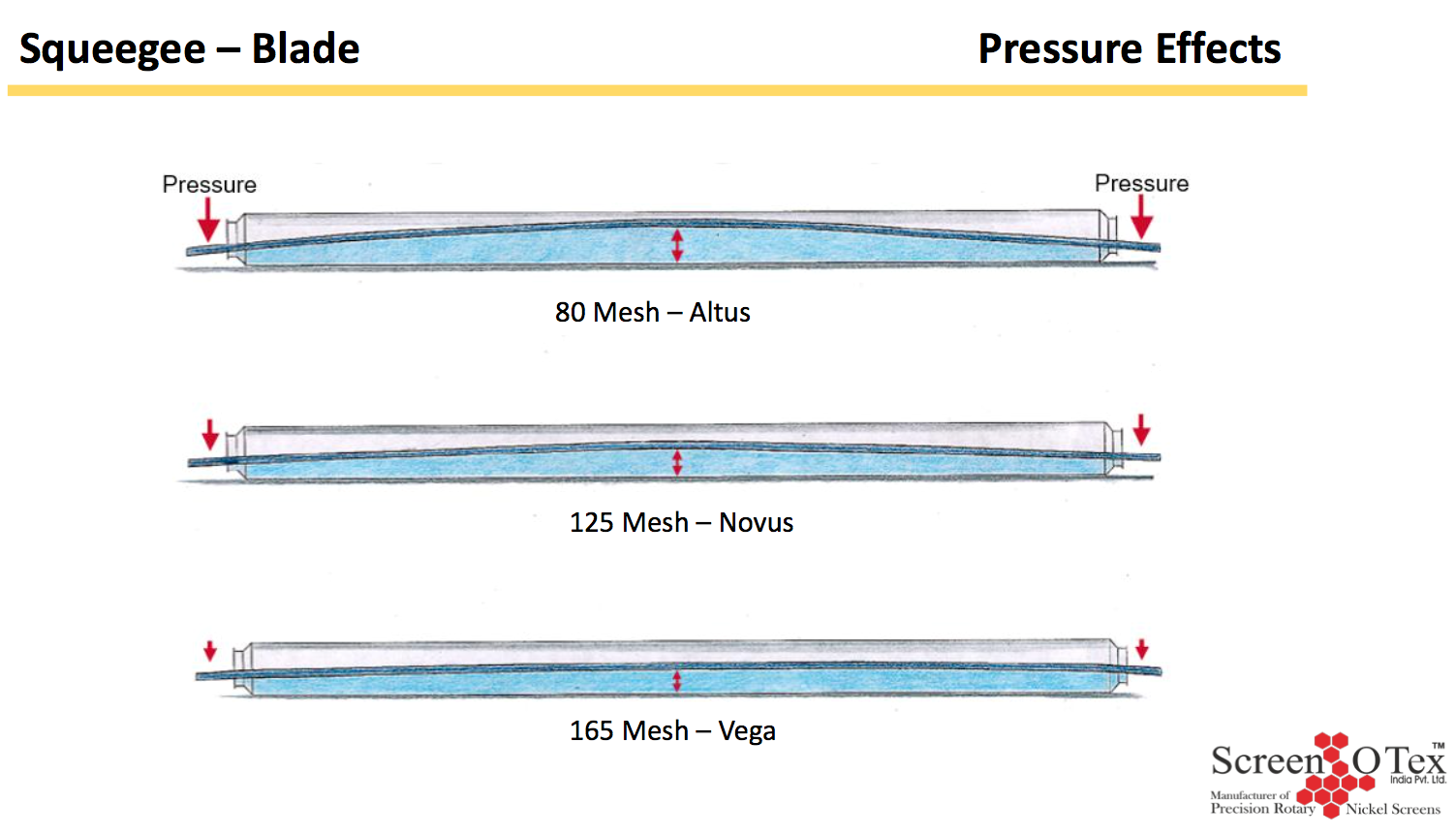

Add a few lines about Squeegee/blade

- Greater Printing Freedom

- Faster Runs

- Less Down Time

- Smooth sailing production process

- Minimize wastage of print paste

- Possible To Print With Higher Viscosity Paste For Sharpest Results

- Improved Durability

- Cost-Effective & Reliable

Recommended Uses

Screen O Tex offers VEGA Screens® in three different mesh counts, catering to every thought and print.

135XT: Highest Open Area, Largest Holes:

Optimal for Blotches, White Pigments, Gold Prints, Thick Substrates

165XT: Popular 3GScreen:

Optimal for combination designs (Halftones, Blotches, Geometrical Designs, Fine Lines)

195XT: Highest Mesh Count, Relative Large Holes:

Optimal for very fine lines, geometrical designs, Tonal Effects